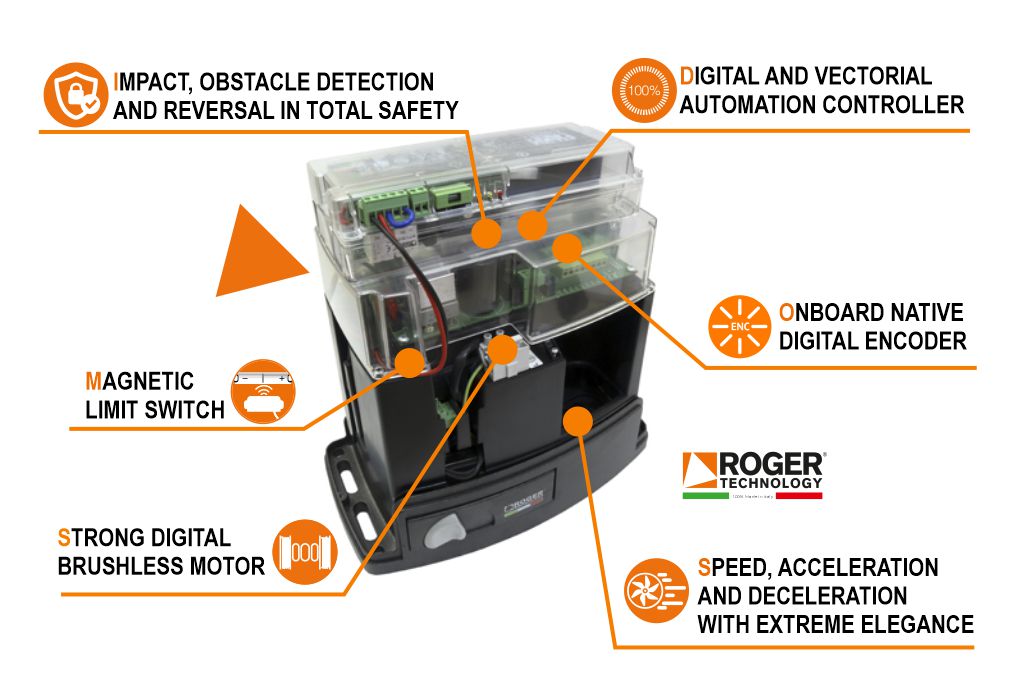

100% Italian Made BRUSHLESS Sliding Gate Motor, Roller/Sliding Gate Opener System.

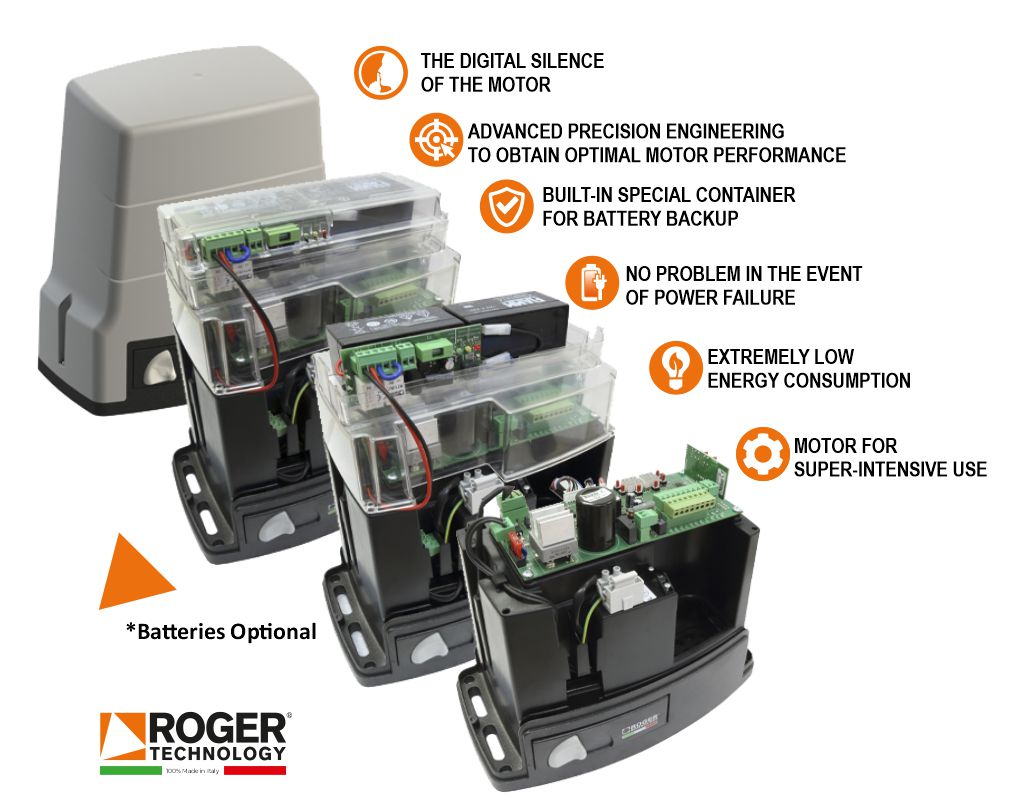

Roger Technology Brushless BH30/804 Sliding Gate Motor

BRUSHLESS 24V Sliding Gate Automation Motor 1000kg Capacity | with magnetic limit switch

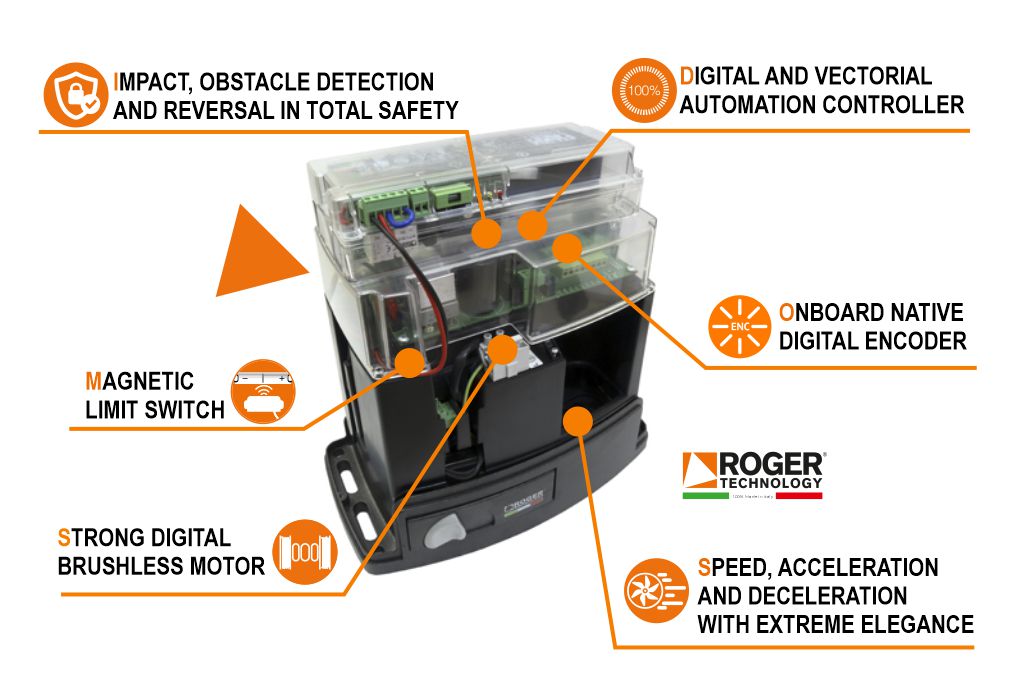

BUILT-IN SPECIAL CASE FOR BATTERY BACKUP

At a glance | Brushless 24v Automatic Sliding Gate Opener / Roller Gate Automation System

The Roger Technology BH30/804 Brushless complete kit includes the roller sliding gate motor, control panel, and receiver.

The BH30/804 motor is a low voltage, super intensive use with native encoder onboard, irreversible ideal for sliding gates up to 1000Kg with built-in digital controller B70 series, magnetic limit switch.

Includes:

- BH30/804 Electromechanical Brushless Sliding Gate Motor

- Built-in B70 24v Digital Control Panel

- Plug-in H93/RX20/I Receiver

- Magnetic Limit Switch

See the full details below.

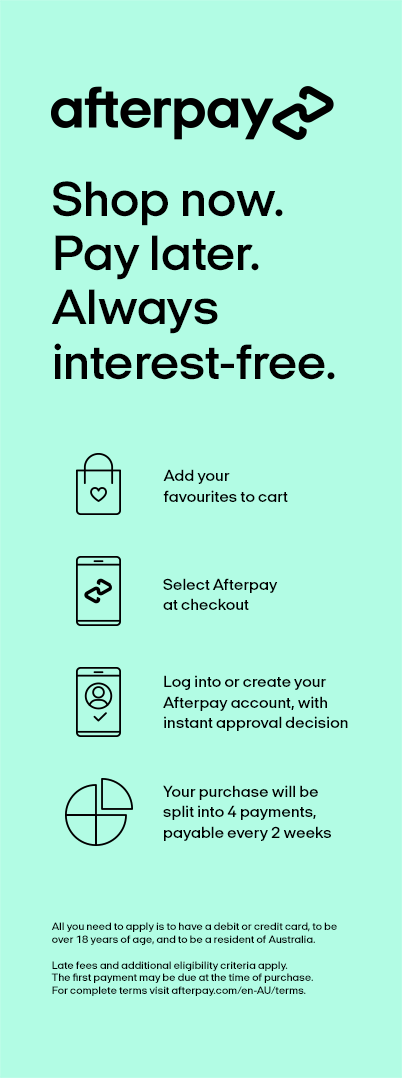

Roller Gate Automation System Features

- Ideal: For sliding gates up to max. 1000 kg.

- Safe: The encoder management allows precise and safe control of slowdown when opening and closing.

- Practical: Automatic programming via the learning function of the control unit.

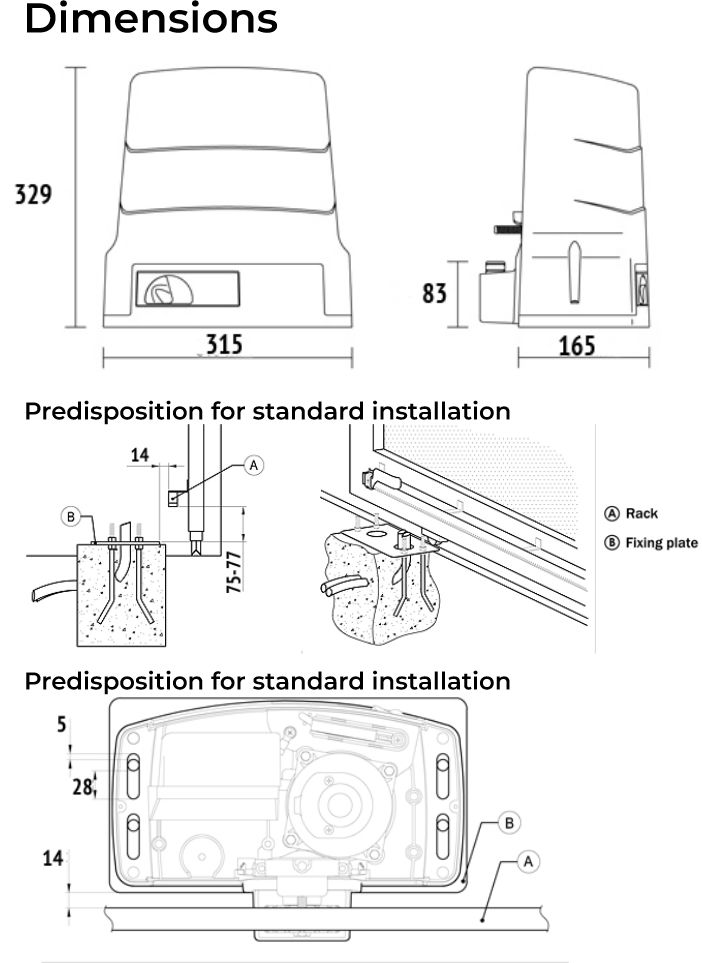

- Quick: Ease of installation and start-up due to its simple functions and its height and depth adjustments.

- Strong: Features a sturdy aluminium base treated with anti-corrosive paint and a reliable Roger Brushless motor mounted in dedicated housings and bearings.

- Equipped with a release lever and an easy-to-operate lock.

- Convenient: Battery backup available.

Capacity

- 100% Duty Cycle (opening/closing - 24 hours, no stop)

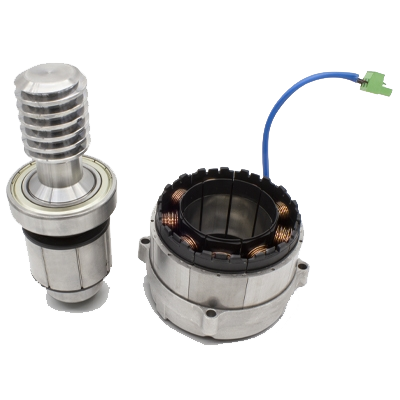

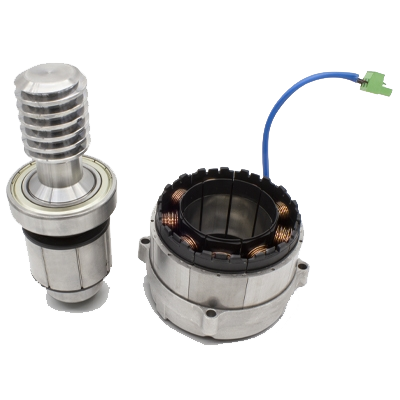

Digital brushless motor based on a permanent magnetic field that uses neodymium iron-boron magnets inside the rotor.

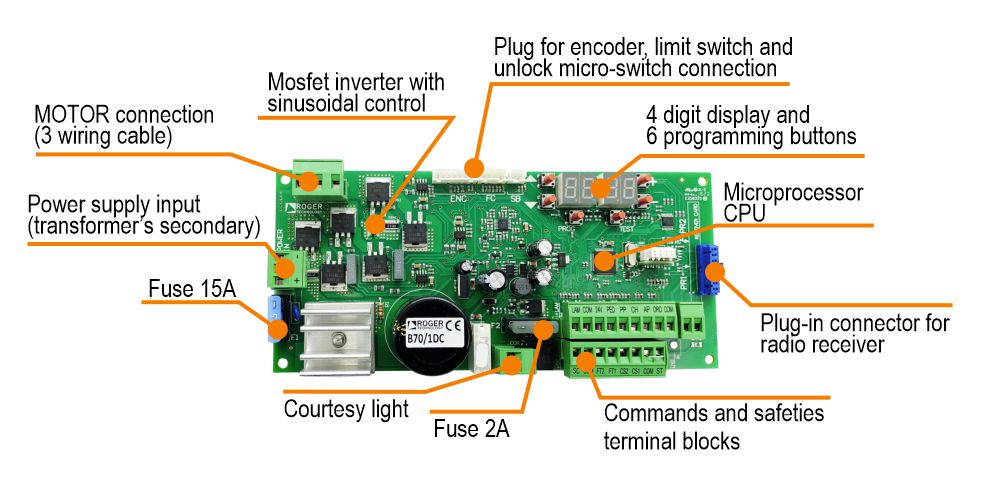

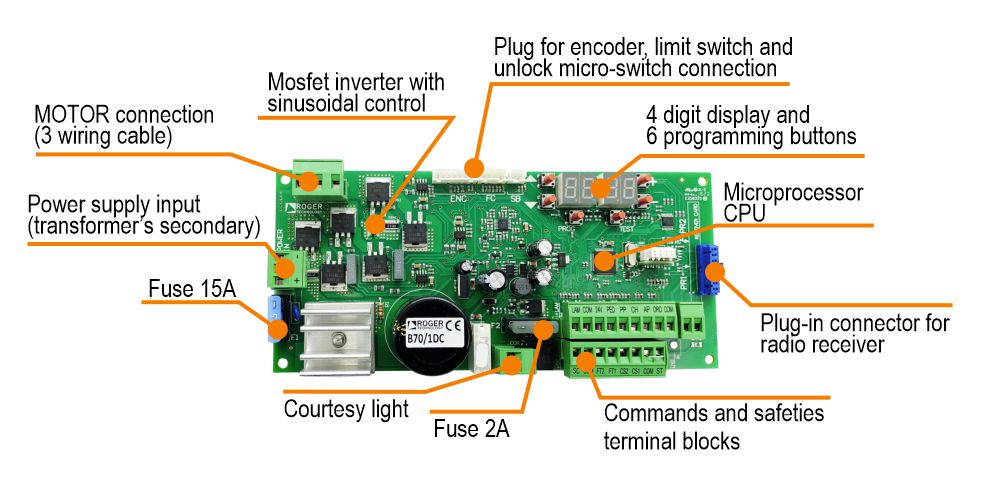

- Multifunction digital display

4-quadrant digital display with six function keys allow you to go through the various parameters, change their values, check error messages and input statuses and perform all the self-learning phases.

- 1000KG Capacity

- Super-Intensive Use; (opening/closing - 24 hours no stop) 1300 | Roller Gate Automation System)

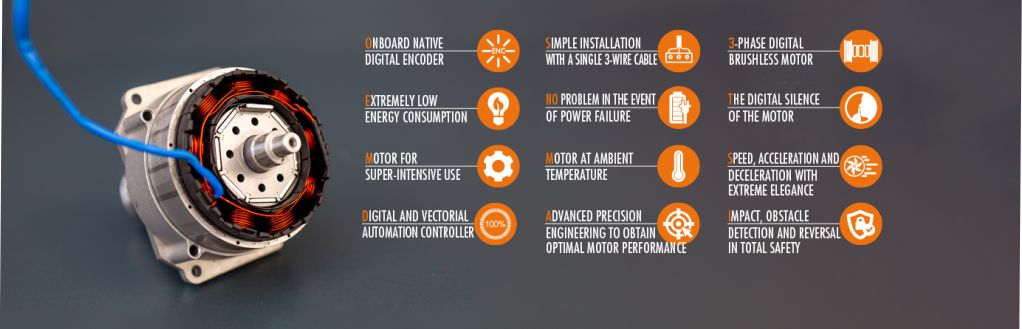

BRUSHLESS MOTOR TECHNOLOGY

A digital brushless motor with a permanent magnetic field and digital electronics for the complete management of the automation system control. Designed for super intensive use with the added benefit of super low energy consumption.

DIGITAL BRUSHLESS MOTOR

Innovative, revolutionary Brushless digital motor with permanent magnetic field, 24V/36V energy sinusoidal with a native encoder that permits highly intensive use of the automation with extremely reduced consumption whilst at the same time fully guaranteeing all its safety and management functions.

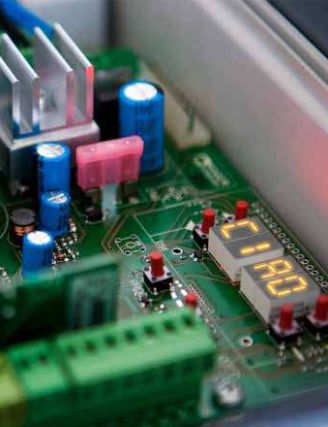

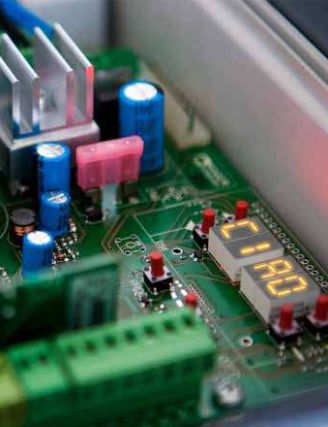

NEW GENERATION OF ELECTRONICS

The new control unit with onboard Brushless digital controller (24V/36V DC). Without traditional relays and thanks to its revolutionary MOSFET quadrant system and its control technology entirely based on a DSP microcontroller, it represents a new generation of electronic cards created to safely handle every type of automation movement.

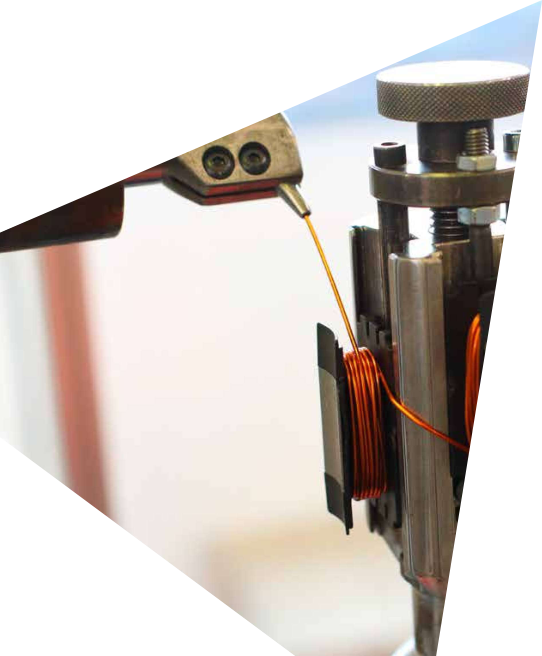

ENGINEERING PASSION

All the mechanical components and gears are manufactured in steel, cast iron and bronze. The automation system casings are made from titanium-reinforced die-cast aluminium. All the gears are inspected and assembled on high-quality bearings and inserted on precise seats machined to provide absolute precision between the axes.

Special Features of Brushless 24v Automatic Sliding Gate Opener

WHY BRUSHLESS...?

WHY BRUSHLESS...?

Digital, smart, powerful, elegant, robust and all-Italian.

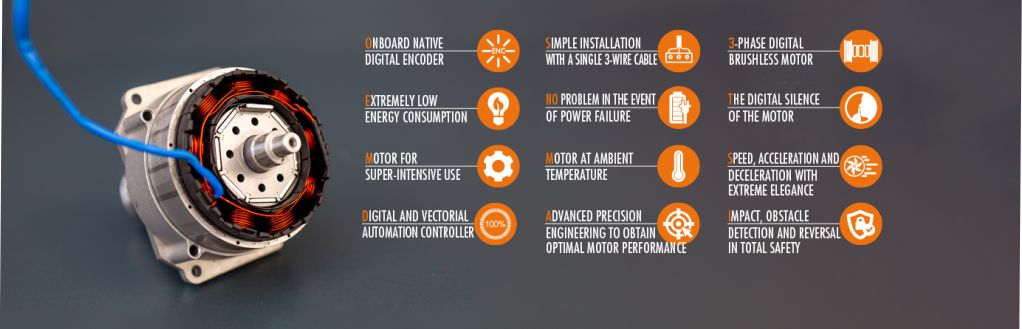

A technology that offers maximum performance but consumes less power than other motors. The revolutionary digital motor with 12 unique features.

Powerful Digital Brushless Motor

A very powerful sliding gate motor with substantial torque. The motor is compact and neat due to the special concentrated coil windings, it is powered by an energy sinusoidal system.

Digital & Vectorial Automation Controller

The BRUSHLESS digital controller, which operates at low voltage DC, allows 100% control of the automation system in digital mode. Due to its operation entirely based on a DSP microcontroller, the travel and your automation system's movements can be programmed and customised easily, precisely and elegantly.

The Digital Silence Of The Motor

One great impact is the silence or the near absence of noise generated by the BRUSHLESS motor during all its movements.

Motor For Super-Intensive Use

The brushless gate motor remains permanently cold even after many days of super-intensive use.

Speed, Acceleration & Deceleration With Extreme Elegance

The automation system with brushless digital technology creates perfect and elegant movements. With a constant force and torque at every point and the option of varying the speed of deceleration and acceleration, the system can be managed with maximum safety.

Extremely Low Energy Consumption

A motor that can operate at low voltage in super-intensive use and operate in environments with highly demanding weather conditions while maintaining very low energy consumption and absorption levels.

Impact, Obstacle Detection & Reversal In Total Safety

Thanks to digital technology, we are able to detect an obstacle and reverse the motor instantly by simply specifying the torque of the motor, the sensitivity, the time and the travel of the reversal, all in full compliance with safety requirements.

Onboard Native Digital Encoder

The BRUSHLESS motor has a highly advanced native digital encoder that controls the management of automation systems in a safe, precise and extremely elegant manner.

No Problem In The Event Of Power Failure

With the help of internal or external batteries and the associated battery charging card, your automation system continues to operate considerably even during prolonged power cuts, ensuring many more operations than traditional technologies.

Motor At Ambient Temperature

The brushless motor was created with the main goal of being a motor for super intensive use and with a 99% efficiency. Regardless of how many operations the engine performs in a day, it always remains cold or, at the most, reaches the outside ambient temperature.

Simple Installation With A Single 3-Wire Cable

And the BRUSHLESS motor can be installed by simply connecting it using a single 3-wire cable! What could be easier? This will provide fully digital management of your automation system thanks to sensorless or sensored technology, depending on the type of automation system.

Advanced Precision Engineering To Obtain Optimal Motor Performance

We have created a mechanism that gives you the opportunity to get the maximum performance out of the motor. A product that combines the quality of the internal production processes, mechanical processing, and high-quality ferrous and non-ferrous materials.

Control Board Overview

Accessories Compatibility and Controlling Options | Sliding Gate Automation

- Constant DC Accessories Output

- Automatic Sliding Gate Open/Stop/Close Inputs for Full Gate Operation and Pedestrian Gate Operation

- Remote controls

- Induction Loops

- Weekly Timers

- Entry and Exit push button with isolation key switches (Wired and Wireless Options Available)

- Keypads (Wired and Wireless Options Available)

- Exit/entry sensors

- Intercom system with dry contact output

- Automatic switching timer

- WiFi Control System (APP-Based Control)

- GSM Control Systems (Mobile Call/SMS-based Control)

Remote Control Features

E80/TX52R/2

Fix code transmitter 433,92 Mhz. 2 channels, with radio for copy.

Technical features

| Standard power: |

3V DC |

| Absorption: |

12mA |

| Operating temperature: |

-10+55 °C |

| The number of channels: |

2 |

| Codification: |

Fix code |

| Modulation: |

AM/ASK |

| Carried frequency: |

433.92MHz |

| The number of combinations: |

65536 |

| Radio for a copy: |

Yes |

| The maximum distance in the open field: |

150m |

| Battery: |

Mod "CR2032" 3V |

Maximum dimension product in mm

(L x W x H): |

38 x 68 x 11 |

| Product weight packed (Kg): |

0,03 |

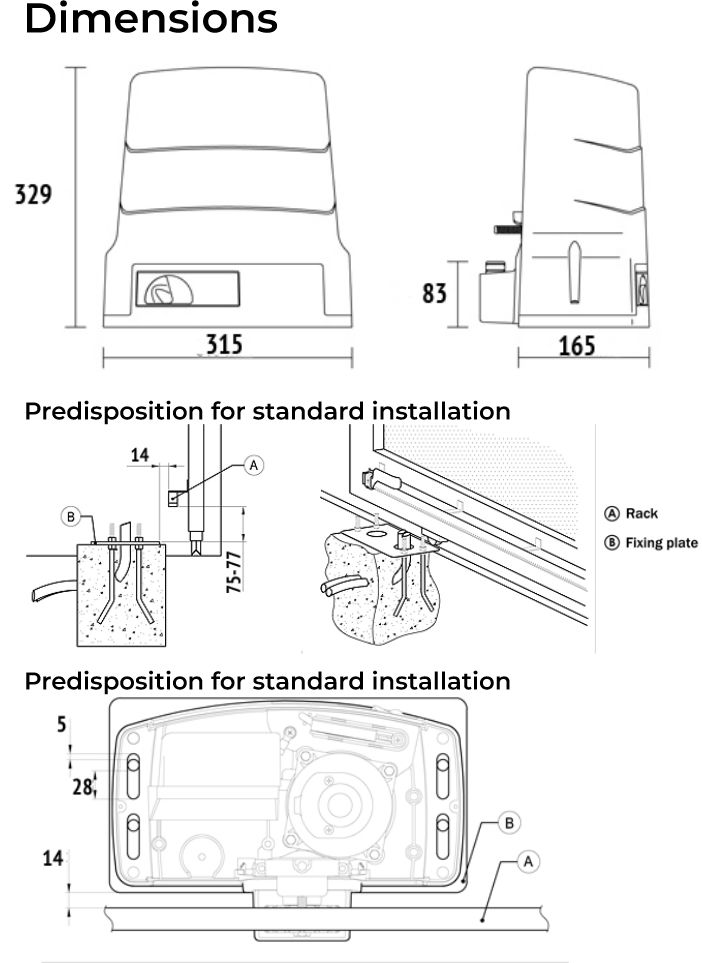

Dimensions | Italian Made Roger Technology BH30/804 Super-Intensive Use BRUSHLESS 24V Roller/Sliding Gate Electric Motor

Specifications

| Max gate weight: |

1000 kg |

| Power line supply: |

230V AC - 50Hz |

| Motor power supply: |

24V |

| Power rating: |

200W |

| Frequency of use: |

Intensive use |

| Thrust: |

50 - 1000N |

| Operating temperature: |

-20+55°C |

| Protection level: |

IP44 |

| Reductor Type: |

Irreversible |

| Manoeuvre speed: |

12 m/min (0.20 m/s) |

| Limit switch: |

Mechanical |

| Onboard control unit: |

B70/1DC |

| Encoder: |

Digital native encoder + magnetic digital sensored, 4096 PPR |

| Batteries recovery: |

Optional 2 internal battery 12V 1,2AH - Optional 2 external battery 12V 4,5AH |

| Type exit gear: |

Z15/mod 4 |

| Operating cycles per day (opening/closing - 24 hours no stop): |

1300 |

| Maximum dimension product in mm (L x W x H): |

315 x 165,8 x 329 |

| Product weight packed (Kg): |

12,3 |

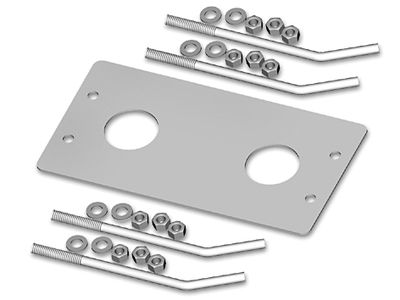

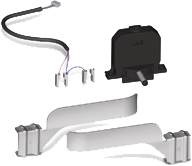

Standard Accessories

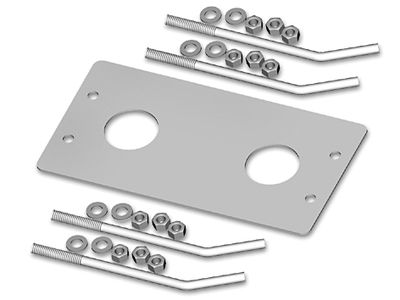

KT223

Fixing plate with stay bolts and screws M30 series.

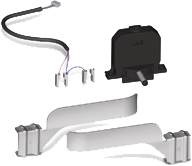

MC775

Kit magnetic limit switch for the control units H70/103AC, H70/104AC, B70/1DC, and B70/1DCHP.

Optional Add-On Raised Fixing Plate

KT220

Raised fixing plate for M30 series (+3 cm).

|

|

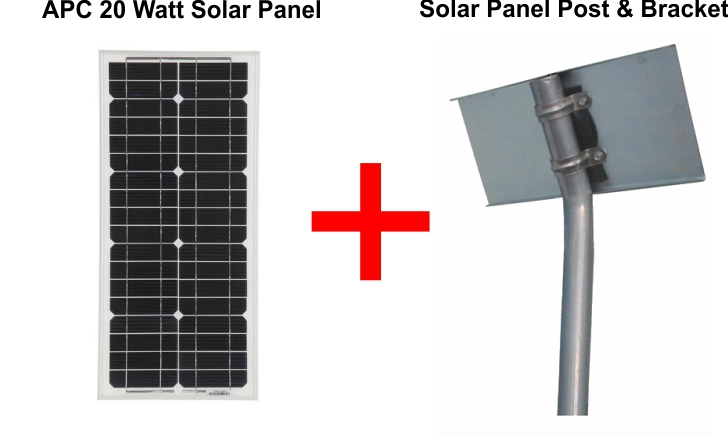

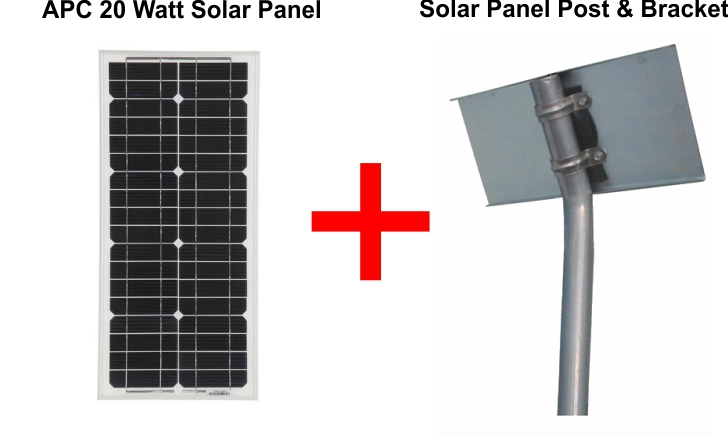

24V 20 Watt Solar Panel

|

|

The SP-24V-20 is a 20 Watt, 24 Volt solar panel, and will provide enough power to trickle charge a 24V vehicle or deep cycle battery. Helps run pumps, lights, fans, and small appliances such as stereos, televisions and VCRs in caravans, boats or cabins.

A heavy-duty anodized aluminium frame provides strength and convenient mounting access. Cells are laminated between high transmissivity, low-iron, 3mm tempered glass and sheet of tedlar-polyester-tedlar (TPT) material by two sheets of ethylene Vinyl acetate (EVA). This protects against moisture penetrating into the module.

|

|

| |

| Open Circuit Voltage |

42.48V |

| Optimum Operating Voltage |

36V |

| Short Circuit Current |

0.61A |

| Optimum Operating Current |

0.55A |

| Dimensions |

640 x 300 x 25MM |

| Cells |

Mono Crystalline |

|

| |

| |

| |

| |

|

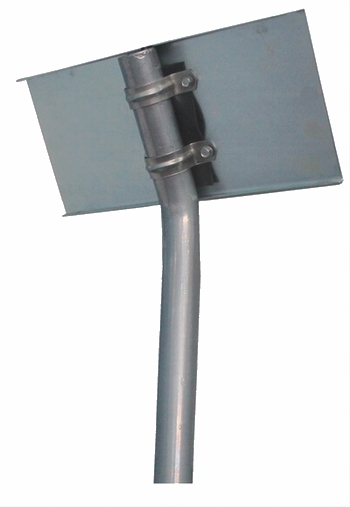

Solar Panel Post & Bracket for APC 20 Watt Solar Panel

|

| |

|

This solar panel post & bracket set is suitable for the APC 10 watt and 20 watt solar panels.

|

|

| |

|

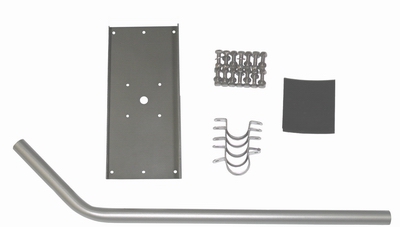

Kit Contents

|

| |

|

|

- Solar Panel Mounting Post

- Solar Panel Mounting Plate

- Nuts, Bolts and Washers

- Saddle Clamps

- Rubber Pad |

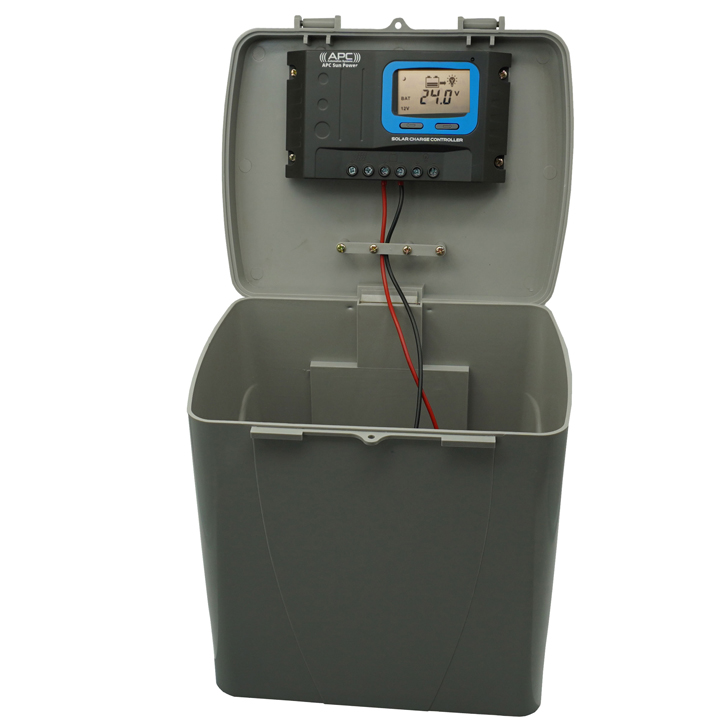

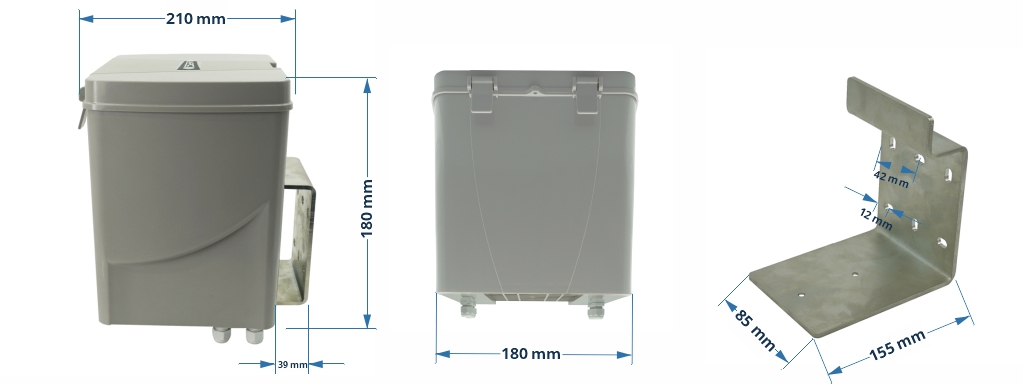

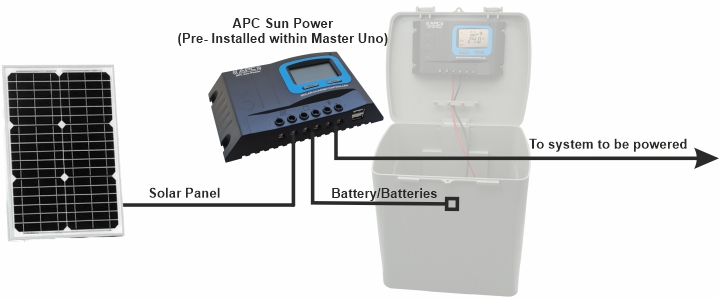

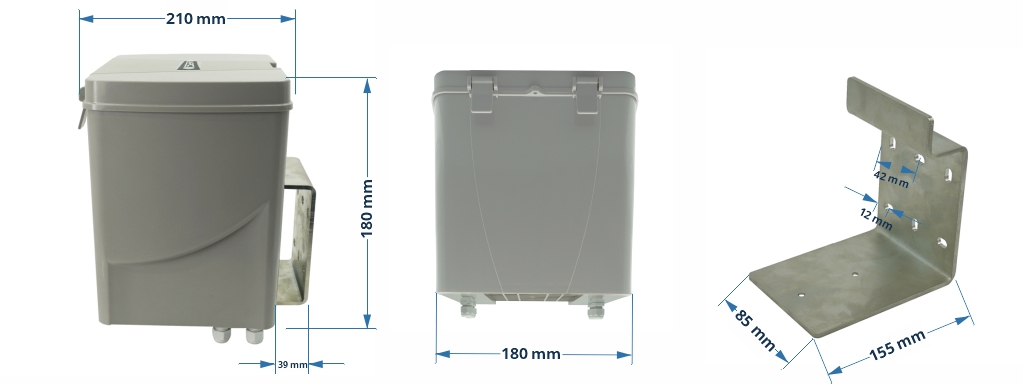

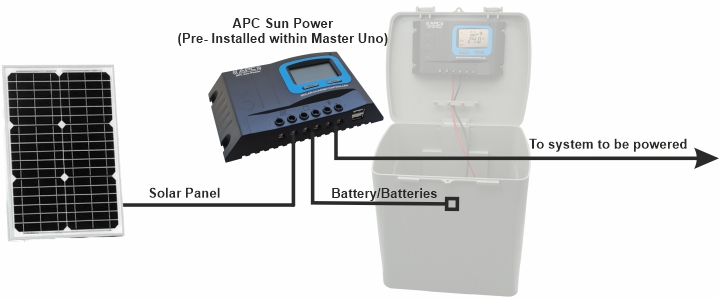

APC Uno Standalone Solar System

The APC Uno is an articulate all in one design allowing for clean and secure housing the APC Sun Power Solar Regulator and multiple batteries.

Key Features:

- APC Sun power Regulator Built In

- Sleek contoured design

- Cable management entries for a clean installation

- Subtle grey to suit all installation environments

- Heavy duty 5mm galvanized 6 hole mounting plate Supports multiple mounting surfaces (piers, posts, walls etc.)

- Easy to access with the tool free clip lock system

- Can be secured with a small padlock

- Four output glands allowing for completely weatherproof entry/exit of cables up to 9mm OD each

Dimensions

Outer Dimensions

| Height |

205mm (Including cable glands) 180mm Without |

| Width |

180mm |

| Depth |

249mm Including Mounting bracket, 210mm without |

Clear Inner Dimensions

| Height |

140mm |

| Width |

165mm |

| Depth |

170mm |

Typical Configuration

At a glance

- 12-24V Compatible

- LITHIUM Battery Compatible

- Easy to use LCD Interface

- Compatible with Most Batteries

- 32 Bit Micro Controller

- Extra Large Wiring Terminals

- 12 Stages of Protection including short circuit, temperature, over and undercharge etc.

- Metal Heat sink

- USB Output

In Depth

The APC Sun Power System can automatically detect the batteries voltage and set itself into the appropriate charging mode of 12V or 24V.

The APC Sun Power can be set to to be used with Sealed lead acid, flooded batteries, gel batteries and even Lithium Batteries.

The APC Sun Power systems built in temperature sensor will automatically adjust the charging voltage to best suit the environment and as a result a 30% increase in battery lifetime can be expected. Furthermore if the ambient temperature within the enclosure it is installed within exceeds 85° Celsius the Sun Power system will automatically turn off.

The APC Sun Power load output will automatically switch off once the load output exceeds 10 Amps (or short circuit) and auto re -try after 30 seconds.

In case of an installation error the Sun Power solar regulator will not be damaged by incorrect polarity on the solar connection or the battery connection.

The Sun Power Series has Two built in USB terminals, each USB terminal is rated to 5V 1A and can be used to operate low current USB devices such as USB powered speakers, tablet and mobile phone charging, warmers, fans etc.

Built to be last and be used in duty applications the Sun Power System not only offers a powder coated steel heat sink backing plate to keep the controller cool in all charging conditions but also has extra large 10mm wire terminals allowing for use with heavy duty cabling, large bootlace crimps or multiple wires per terminal.

Specifications

| System Voltage |

12V/24V DC auto |

| PV Max Input Voltage |

55V |

| Self-consumption |

10mA |

| Max Charging current |

10A |

| Max Discharging current |

10A |

| Battery type |

Sealed(Default)/Gel/Flood/Lithium |

| LVD |

11.0V ADJ 9V...12V ; x2/24V |

| LVR |

12.6V ADJ 11V...13.5V ;x2/24V |

| Float Voltage |

13.8V ADJ 13V... 15V ; x2/24V |

| Boost Voltage |

14.4V ADJ 13V...17V ;x2/24 |

| battery voltage less than 12.6v auto boost 2hours |

| Battery Over Voltage |

16.5V ; x2/24V |

| Reverse Connection Protection |

Yes |

| Load Over Current Protection |

Yes, each 30s auto restart again |

| Controller Over Temperature |

Yes |

| USB Output |

5VDC/1A 2PCS |

| Charging Type |

PWM |

| Charge circuit voltage drop |

<=0.25V |

| Discharge circuit voltage drop |

<=0.1V |

| Temperature Consumption# |

For 12V system:-24mV /°C ; x2/24V |

| Relative humidity |

≤95%, N.C. |

| Working Temperature |

-20°C~+55deg;C(Product can work continuously at full load) |

| LCD temperature range |

-20°C~+70°C |

| Waterproof grade |

IP32 |

| Mounting hole size |

Φ5mm |

| Terminals |

10mm²/8AWG |

| Weight |

245g |

| Overall dimension(mm) |

190×108×41.5 |

APC-RR-11 Retro Reflective Sensor

The retro-reflective Safety sensor set is used to prevent the closing cycle occurring during the case of the sensor path being interrupted by vehicles, trailers or any other obstacles.

If the gate begins to close and the sensor path is interrupted then the gate will stop and return to the open position.

The sensor ( which is the transmitter and receiver) is wired back to the control box of the gate system using the pre-connected cable. There is no requirement for wiring across the driveway using this type of sensor.

- Up to 11 Metres Infrared beam operating distance

- Only powers on when the command is given to close the gates

- Alignment & Misalignment led to assist in the installation process

- Resin filled for the ultimate weatherproofing

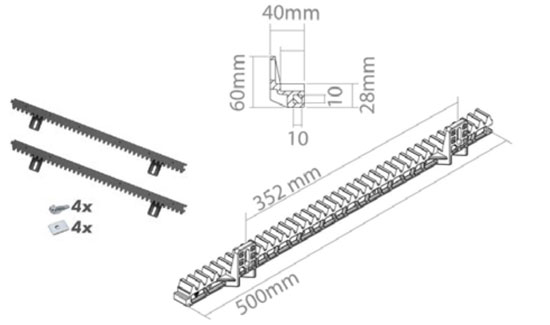

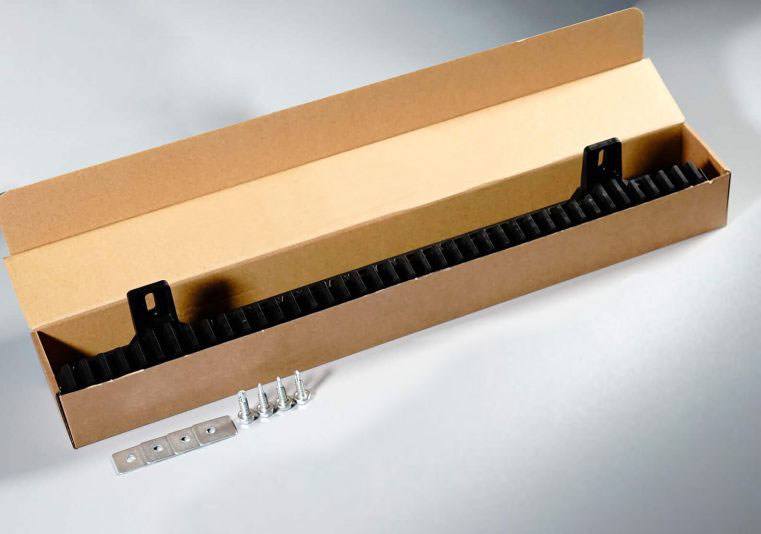

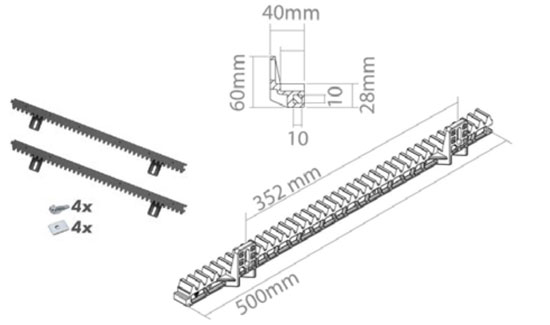

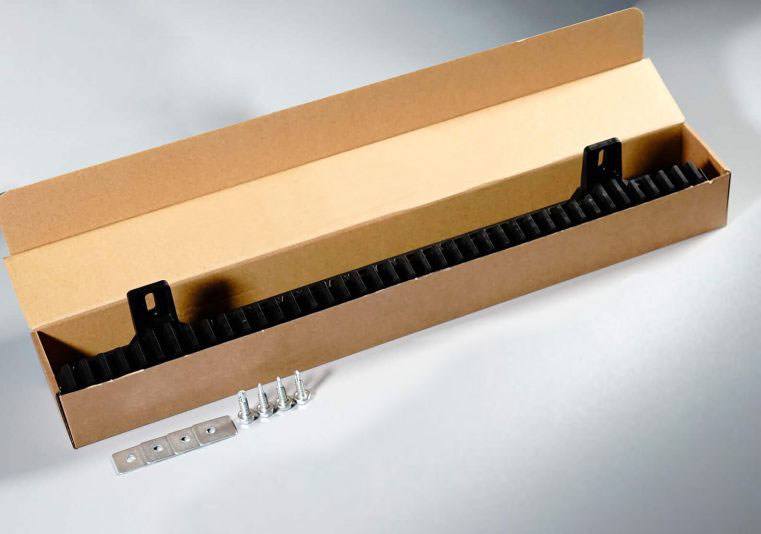

(2 x 50 CM) Nylon Gear Racks 1 Meter Pack | Made in Italy by Stagnoli

Interlocking Gear Racks Made in Italy by Stagnoli

The Keyed Interlocking Modular Nylon Gear Rack is Compatible with All Sliding Gate Automation

Stagnoli, Italy invented the nylon racks and has been manufacturing nylon racks since 1981. The advantage of nylon racks is no lubrication, rust-free and silent. Furthermore, with the nylon rack, there is no need to carry out any welding, which is instead required for iron racks and which involves more machining in the assembly process. GR50 is a quality product and is completely Made in Italy.

Dimensions of Modular Nylon Gear Racks | Sliding Gate Hardware

This gear rack nylon coated with steel core, strong and quiet, is compatible with all sliding gate automation, and is easy DIY install.

Modular gear racks kit includes;

A box with 2 nylon gear racks measuring 50 cm, 4 self-tapping and self-piercing screws, and 4 washers in galvanized steel. (Made in Italy by Stagnoli)

Free Shipping

Free Shipping

WHY BRUSHLESS...?

WHY BRUSHLESS...?