APC-GE400 Gate Extension System

Ingenious sliding gate tail section system can be used in a variety of different applications without any welding required, such as:

- Changing from a swing gate to a sliding gate, you can now utilize the existing gates together and add on the top and bottom tail sections to extend the gate for sliding use.

- Increasing a driveway width by extending an existing sliding to become a longer

- Errors made in calculation or manufacturing for the size of a sliding gate can now be resolved without any need to re-manufacture.

- Cost-saving, you can purchase a shorter in-width gate and add the section to extend its total width.

- Letterboxes in the gate area, using a shorter in-width gate and extending using the tail section allows for a clear area for the user to reach the letterbox.

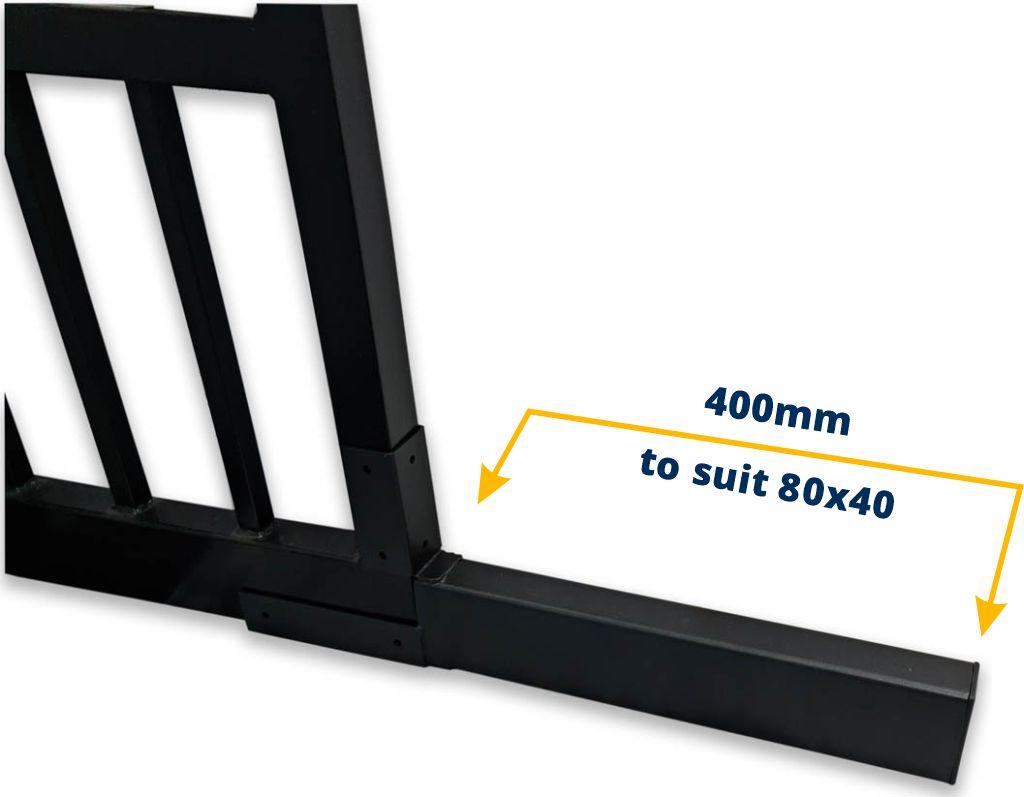

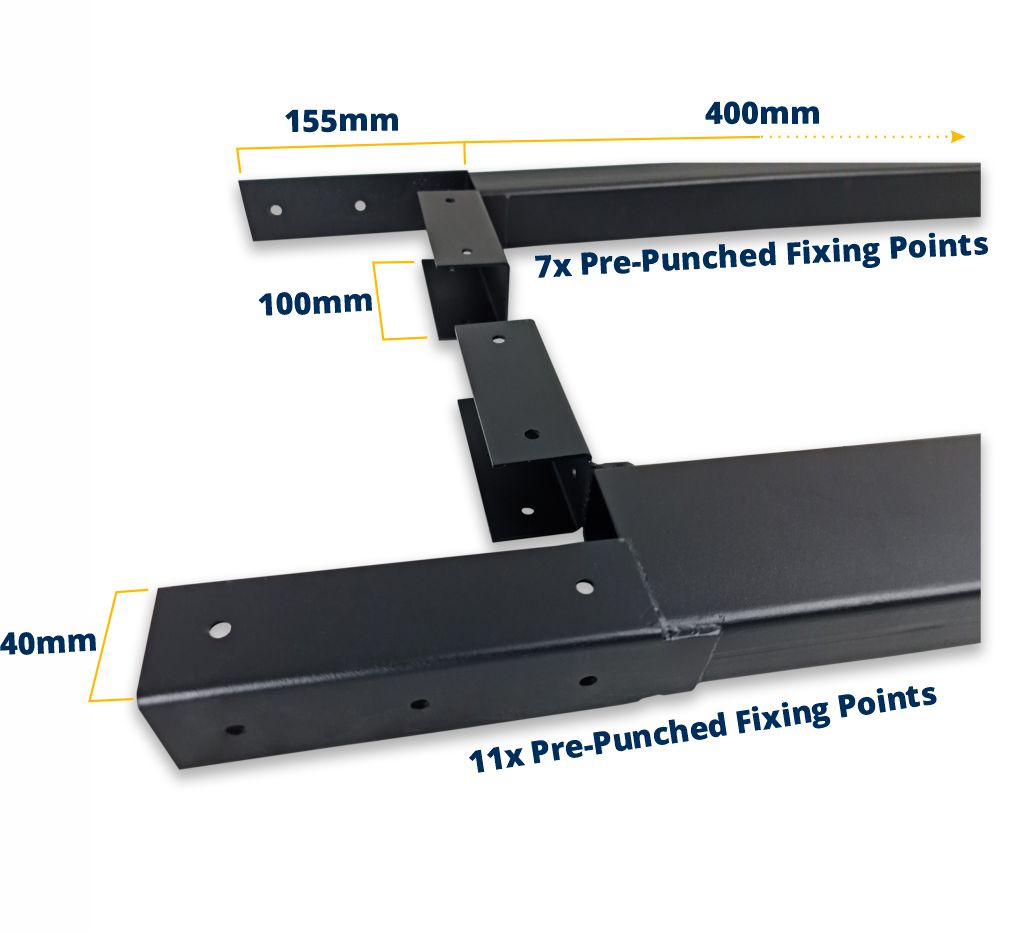

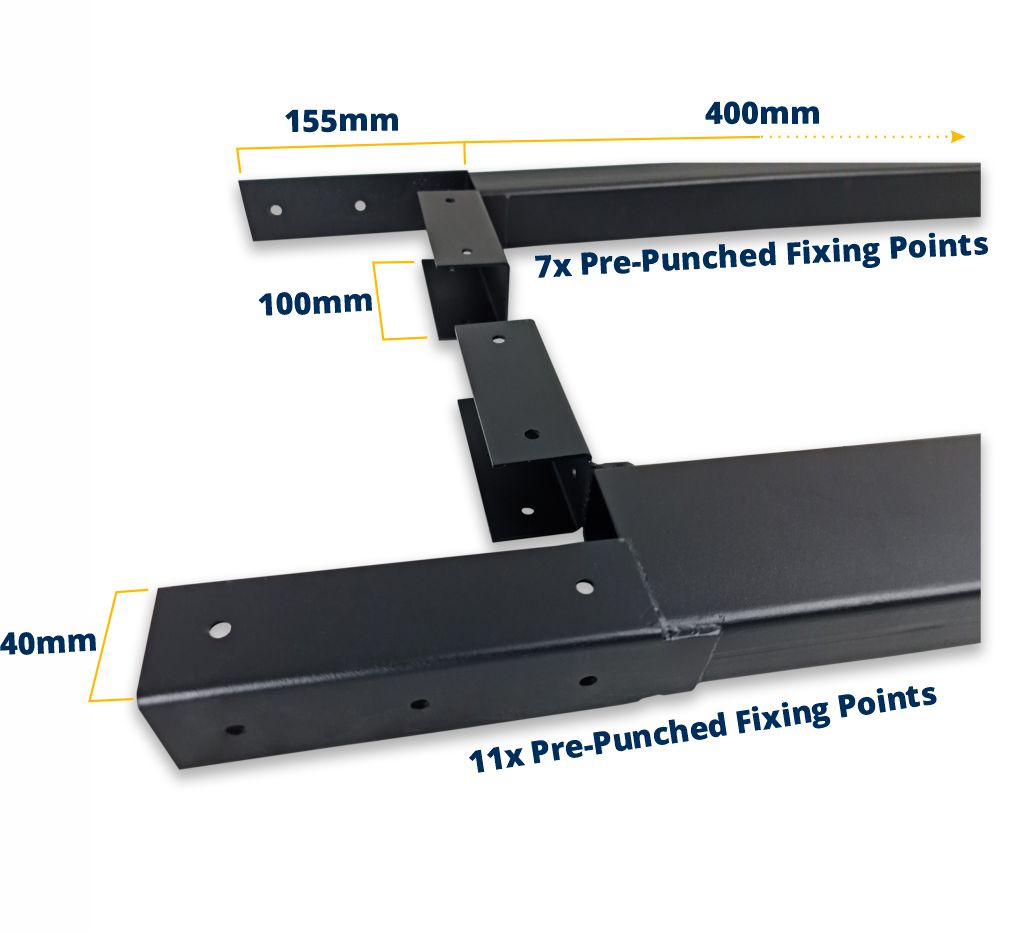

Bottom Tail Construction

The bottom tail section is constructed out of 80x40 RHS steel to allow for the installation of sliding gate gear rack systems in automation applications. Just like the top section, the bottom is also manufactured with two additional bracing brackets welded it allowing for a seem less tie-in as if the gate was manufactured for sliding use.

- The bottom bracket is to allow the section to clamp and fix to the underside of the gate by 150mm and also the sides of the gate for a solid weld-like fixing with pre-drilled holes to screw through using the supplied self-drilling screws.

- The side bracket is to allow the section to clamp to the sides and also the back of the gate for a solid weld like fixing with pre-drilled holes to screw through using the supplied self-drilling screws.

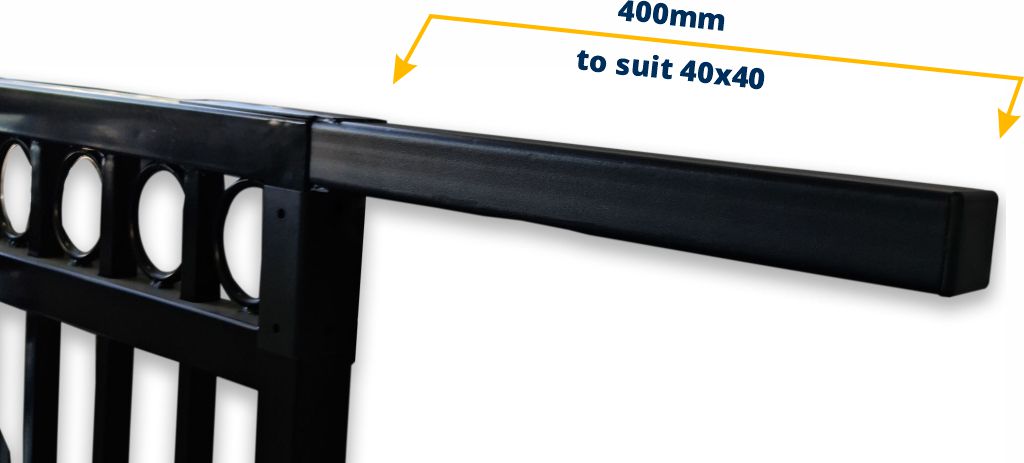

Top Tail Construction

The top tail section is constructed out of 40x40 SHS steel to allow for use with roller guide systems and is also compatible with Z channel guide block systems. Manufactured with with two additional bracing brackets welded it allows for a seem less tie in as if the gate was manufactured for sliding use.

- The top strap bracing is to extend into the existing gate by 150mm to keep the section level with the top, with 3x pre drilled holes it allows for fixing into the existing frame using the supplied self drilling screws.

- The bottom bracket is to allow the section to clamp to the side of the gate for a solid weld like fixing with pre-drilled holes to screw through using the supplied self drilling screws.

Dimension Overview

What's Supplied

- 22x Powder-coated black pan head self-drilling metal screws

- Powder-coated steel 40x40 top section with cap for exposed end

- Powder-coated steel 80x40 bottom section with cap for exposed end

FAQ

Q: What size tube will this section work with?

A: 40x40 top and 80x40 bottom; see the next question on how to use with larger tubes

Q: Can it be used with a 50 mm profile tube?

A: Yes, it would require a cutaway from the street side of the tail section, and it will align flush with the back of the gate.

Q: Wouldn't there be a problem using the upper roller guides with this system?

A: No, there wouldn't be an issue, as the top section clamping bracket is designed to start below the bottom tube to allow for roller use without conflict.

Q: Will there be movement from the section once it's installed?

A: Only very marginal movements <1mm